Model DH831 Dispersible Performance Tester

Product model:

6

Product Features

Product Details

Scope of application: It is applicable to the dispersibility test of non-woven disposable sanitary materials that can be dispersed and degraded directly into the toilet bowl, including wet toilet paper (dry/wet wipes for toilet use), dry/wet wipes for female hygiene and dry/wet wipes for special hygienic care of infants and young children.

Applicable standards: GB/T40181-2021 dispersibility test method and evaluation of non-woven materials for disposable sanitary use.

Technical index: 1. Time setting range: 0-99 minutes and 59 seconds.

2. Speed range: 0-50 rpm

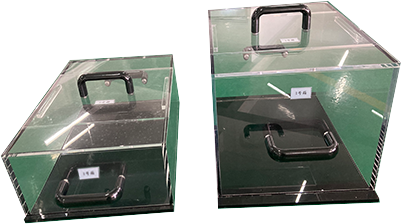

3. Shaking box: 3 (national standard, Japanese standard optional)

4. National standard mesh screen: Φ200, mesh: Φ12.5 Day standard mesh screen: Φ200, mesh: Φ25

5.Power:AC220V/50Hz

6.Power:1000W

7.Overall size:1050×580×580mm

8.Weight:123Kg standard

List of accessories:

Standard test box (national standard, Japanese standard)

Standard sieve mesh

Standard filter mesh

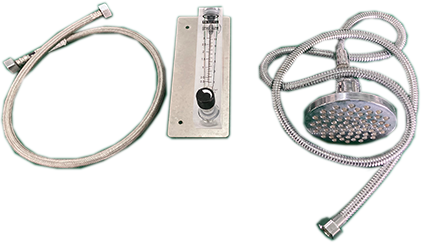

Standard nozzle assembly Stopwatch

stopwatch

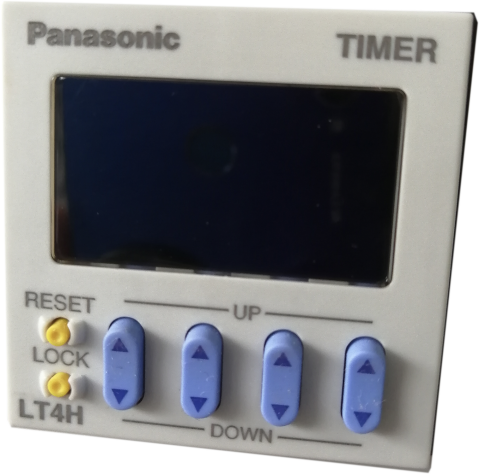

Panasonic Dual Digital Time Controller Mitsubishi Electric Inverter

(ATL5187) FR-D720S-0. 75K-CHT

(One year warranty) (One year warranty)

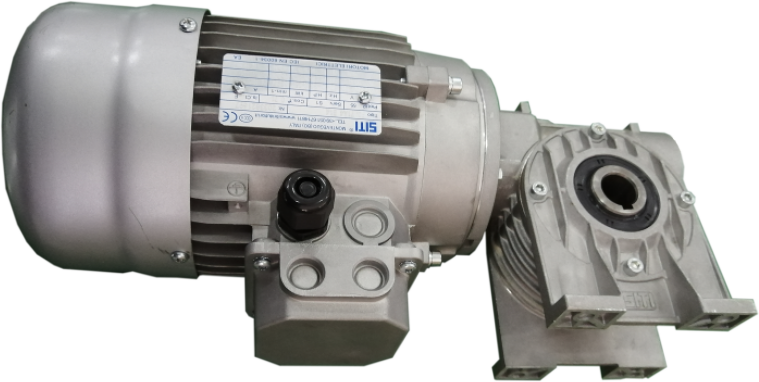

SITI Motors and Gearboxes

m140 a p71b14 \71a4

(Warranty one year)

Product Manual:

The instrument is designed by absorbing the advantages of similar instruments at home and abroad, adopting imported AC servo drive system, timing system, speed test system; making the instrument easy to operate, stable operation, low noise and convenient maintenance.

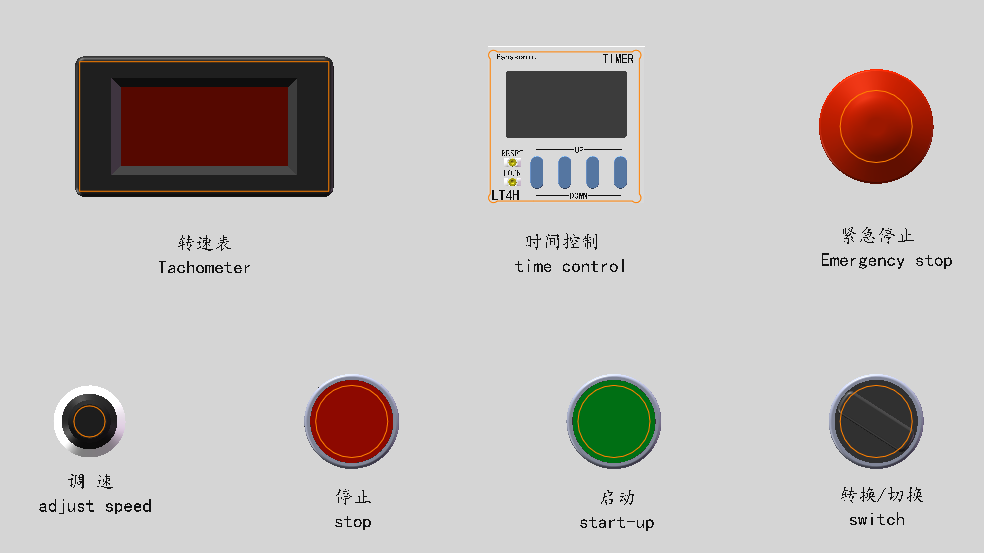

Indicators (see above)

Structure and working principle

1. Product panel diagram

2.Main components

There are four foot screws at the corners of the instrument base, all of which are adjustable, and the adjustment of the foot screws can make the instrument in a stable and horizontal state; the upper part of the instrument base is equipped with a motor servo system, an instrument speed-regulating and speed measuring system, and a motor cooling and circulating system.

3.Testing Principle

The specimen is placed in a shaking box with 2L of tap water, oscillate at a certain frequency and amplitude for 60 min, then transfer the specimen to a porous sieve with an aperture of 12.5mm, collect the specimen left on the sieve porous sieve and weigh it, and calculate the dry weight of the specimen through the sieve mesh as a percentage of the dry weight of the original specimen.

Third, the operation of the instrument

1. Switch on the instrument, rotate the ‘Emergency Stop’ button and turn on the power.

2.Time setting

Adjust the ‘▲’ and ‘▼’ on the 4 rubber buttons on the time timer to adjust the 10th digit of minutes, the 1st digit of minutes, the 10th digit of seconds, and the 1st digit of seconds respectively; set up and the data will be saved automatically.

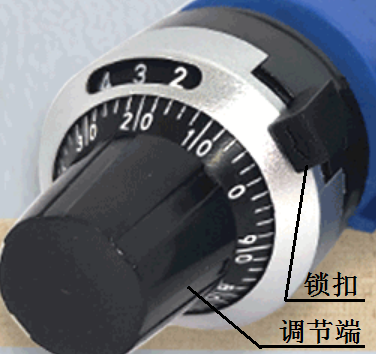

3.Speed Adjustment

After switching on the machine, release the lock, adjust the ‘speed’ knob, observe the XX revolutions/minute on the tachometer, and lock the lock after reaching the target speed.

4.Start and stop

Press the green ‘start’ button, the machine starts, the shaking box swings back and forth; press the red ‘stop’ button, the machine stops, the shaking box stops shaking.

5. Conversion/Switching

After pressing the ‘Stop’ button, the instrument does not necessarily stop in the horizontal state, then you need to twist the ‘Convert/Switch’ button, the instrument runs to the horizontal, stop running, release the ‘Convert/Switch’ button, the button automatically reset. After the instrument runs to the level and stops running, release the ‘Convert/Switch’ button, the button will be reset automatically.

6. Switch off

When the instrument is finished using, press the ‘Emergency Stop’ button, the instrument is powered off and the shutdown is completed.

Maintenance of the equipment

1. Keep the equipment clean and hygienic. 2.

2. Prevent high temperature, excessive humidity, dust, corrosive media, water and so on into the machine or control system.

3. Regular inspection to maintain the integrity of parts and components.

4. Pay attention to the easy to rust parts, coated with anti-rust oil.

5. Non-professional maintenance, verification personnel shall not dismantle the instrument.

6. During the use of the machine without the consent of the company to privately modify the machine and cause damage, the company will not be responsible.

7. The company is not responsible for all the consequences caused by not operating according to the precautions and requirements of the manual.

About Us

Contact Information

Contact: Zhang Chunmei

Mobile:19957061161After-sales contact:0574-89110834

Landline:0574-89110834E-mail:476123487@qq.com

WeChat Sweep

Online message

Copyright © 2024 All right reserved Ningbo Dahe Instrument Co., Ltd. Website Construction:Xinnet